Are you thinking of starting out in brewing or already in the process of setting up? Are you keen to learn more about the realities of chasing that dream: the highs, the lows, the hidden surprises?

Here, we ask the owners of four Australian brewing companies what they've learned in their first year of operation.

If you'd like to find out even more, The Crafty Pint is hosting a Brewery Startup Panel with Cryermalt and a number of beer industry experts during Good Beer Week. To find our more, or to apply for seats at the panel, head here.

Tallboy & Moose

Tallboy & Moose is a brewpub operation in the northern Melbourne suburb of Preston. It was opened late in 2016 by Steven "Moose" Germain (above left) and Dan "Tallboy" Hall, who had first tested the waters with nano batch brewing under the We Make Beer banner. They currently brew into three 1200 litre fermenters on a brewery they designed and built themselves on a tight budget. Their biggest selling beer is their Cream Ale.

Where did you expect to be at this stage?

Steven: We started up with a break even strategy, paying ourselves less than minimum wage and hoping to be selling enough beer to cover our bills, staffing costs and loan repayments. Ultimately, we just needed to get the brewery off the ground and moving forward... and having multiple potential business models in our initial plan, we knew that we would need to be flexible and adaptable to make it all work.

Where are you in relation to that expectation?

We have really just started to find our feet. Sales volume has been good and met expectations in-line with our business plan models. Being just over five months old, one of the tricky bits has been dialling in our production schedule. Ramping up initially after opening we could not make enough beer to keep up... now we are working out the sweet spot in our production schedule in order to balance batch sizes and throughput for wholesale vs bar sales. We are also at a stage where we are starting to think a few months ahead in order to plan for next steps.

Knowing what you know now, and given the chance to start over, what's the one thing you would do differently?

If there was anything I'd change it might be raising more upfront capital. It could have given us the ability to be more aggressive in certain areas of the startup phase. Having said that, we have gotten by on a very limited budget as far as brewing operations are concerned. The downside to raising more capital is being more heavily in debt.

I suppose there is a balance there, and I can say that I'm happy not to be more in debt that we are at the moment.

Would you do it all over again?

Yes, we made a decision to dive in the deep end, and I think that decision would have been made one way or another regardless of the project.

What has surprised you the most?

The incredible interest and support in our community. Being a brewpub, our ultimate goal is to become a local classic... and you can't do that unless your local population supports you 100 percent. The general attitude of the locals in our area is amazing and is a massive driver for us to keep chugging along every day. Our customers are honestly just really nice, good friendly people and we are incredibly appreciative of that.

What has been your greatest victory to date? And your biggest mistake?

I think our greatest victory is the quality of beer Dan has been able to push through an extremely quirky brewhouse. Having built a lot of the brewhouse ourselves, the efficiency and final profile of the beers has really surprised us... I guess that's step one for a brewery, make sure your beer is top notch.

As for the biggest mistake, weather and production scheduling are two areas we underestimated. Weather can have a massive impact on a venue like ours (big warehouse) and we could have planned better on heating and cooling at an earlier stage. As previously mentioned, we got caught out early on and were running out of beer... We could have scaled our production plan a bit better in the early days... but we continue to learn and make tweaks in this area!

What advice do you have for anyone following in your footsteps?

Have a razor sharp, detailed budget for your business plan and make sure you have plenty of flexibility when it comes to startup capital. Plan for the unexpected and have backup models if certain channels of your business don't go according to plan.

Describe the process of starting a brewery in five words?

Challenging, rewarding, time-consuming, stressful, delicious.

Sauce Brewing

Sauce Brewing will ultimately call Marrickville home. Owner Mike Clarke is in the process of building a production brewery there, which will also include a retail side open to the public.

He has launched the business as a gypsy brewer, utilising spare capacity at Hairyman Brewing and has already released four canned beers into the market. Once his four-vessel system, with 24,000 litres of fermentation space, is up and running, Sauce will be capable of producing 400,000 litres per annum, scalable to 800,000 litres.

His biggest seller is the Hop Sauce Pale Ale, with the others (IPA, double IPA, Saison) "not too far behind".

Where did you expect to be at this stage?

Mike: I started down this path early 2016 so I was hoping to have my own venue open by Christmas 2016. Unfortunately, industrial property was pretty thin on the ground in the areas I was looking so it was nine months before we signed a lease! So that, of course, pushed everything back and is also the reason we started gypsy brewing last year – to get the brand in market prior to the brewery being built.

Knowing what you know now, and given the chance to start over, what's the one thing you would do differently?

I would probably not start gypsy brewing before opening the brewery. Although it’s been a successful brand-building exercise, it is costly and also distracts you from the more important work of building your brewery.

What has surprised you the most?

I didn’t expect the cans to take off the way they did. With our first brews, we put more beer in kegs than we did cans and then we sold out of cans. The cans almost sell themselves and we’re fielding daily enquiries from around the country!

What has been your greatest victory to date? And your biggest mistake?

The victory is a collective one – getting the brand to where it is in a fairly short space of time. The next great one will be opening the brewery and taproom! Biggest mistake – probably spending too much time (and capital) on the gypsy phase of the business.

What advice do you have for anyone following in your footsteps?

Research the shit out everything before committing to anything or spending money. Understand and accept where your knowledge or experience falls short and get professional advice or training in those areas. Make sure you have a BIG contingency fund in your budget. Everything costs more and takes longer than you think.

Describe the process of starting a brewery in five words?

Exciting, time-consuming, expensive, fun.

Otherside Brewing

Otherside Brewing is a Fremantle based brewing company launched in 2016 by Seb Levy (above left) and Rhys Lopez (right). The pair is currently brewing its beers as a gypsy operation and recently launched its first canned beer, brewed and packaged at the Beer Farm in Metricup.

Where did you expect to be at this stage?

Rhys: According to our first plan, by now we would have a kit on the way from China, destined for a small brewery/venue on the water in Fremantle. We fell in love with a site and formed a plan long before investigating the sewage/power/gas requirements. All of these were to be found lacking. Fixing these would have unfortunately been more expensive than the brewery build itself, so the idea was abandoned.

According to the second plan, by this stage we would be producing wort offsite at a contract brewery and then fermenting it in our tank farm, located in the warehouse at the back of our offices in Freo. This would have been a logistical nightmare, so I am somewhat thankful that we changed directions again. Right now we would be ordering a brew kit for the warehouse space.

Where are you in relation to that expectation?

We adjusted our plan once it became apparent that neither site was adequate for what we needed. Currently we are working on a production brewery in an industrial area, separate from our venue (which was a plan for further down the line). So, rather than ahead or behind, we are more sidelong to the original idea.

In terms of knocking out beers, we have been lucky enough to have a few strong relationships with other breweries who are kind enough to let me use their tanks. We have proceeded to release just two beers so far, which is right on cue.

Knowing what you know now, and given the chance to start over, what's the one thing you would do differently?

There can be many hidden obstacles that pop up on your journey down a particular path – and the natural (optimist’s) reaction is to deal with them as they occur and keep on going – but it is good to have a line in the sand where an idea is no longer worth pursuing. Otherwise it is easy to get stuck in an expensive sunk cost fallacy.

Would you do it all over again?

All of it, really. There have been a lot of fun times in our tight knit team. Things that I thought were mistakes at the time turned out well. I’d probably have skipped right to the current plan, but that’s all part of the learning curve.

What has surprised you the most?

What surprised me the most was how much support we have received. From other brewers, venues, bottleshops and beer nerds. People really want to see small independent brewers succeed.

I constantly hit people up on Facebook or on the phone and ask questions. How much should I charge for X? Who could certify a pressure vessel? How much space should I dedicate to a cool room? Things like that.

What has been your greatest victory to date? And your biggest mistake?

From my perspective as a brewer, the hugely successful launch of the Harvest Red Ale was a highlight. We are producing down at the Beer Farm in Metricup, and getting that first can off the line and holding it in my hand was a beautiful moment for me. I am looking forward to a similar experience when I order my own beer at GABS this year. Due to circumstance, it will probably be my first chance to taste it as a finished product.

As for biggest mistake – falling in love with the sites that we liked, without first considering whether it was appropriate. Quote gathering takes time, and slowly the realisation dawned on us that we’d need to find another place, but by that point we had spent a lot of time on a plan that we couldn’t use.

What advice do you have for anyone following in your footsteps?

Look at the bones of a building first, rather than aesthetics. Upgrading water, concrete, power or sewage can end up more expensive than your stainless steel. Once one aspect changes all the decisions that connected to that thing need to be reconsidered. The best decision for one brew kit or location might be quite different from another, despite how similar they appear. Get the foundations right and build from there.

Describe the process of starting a brewery in five words?

Educational, stressful, exhausting, drunken fun.

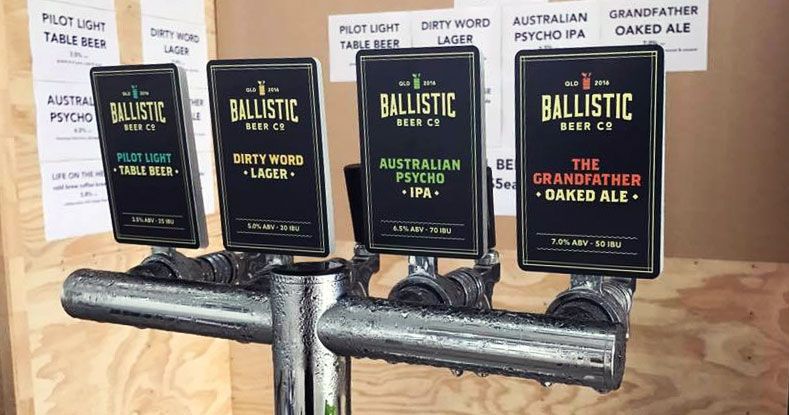

Ballistic Beer Co

Ballistic is one of the newest arrivals on the booming Queensland brewing scene – and plans to be one of the biggest too. Founded by former chartered accountant, banker and diplomat David Kitchen, known to many in the beer scene from his Brewer's Choice home brew stores, and with well travelled young brewer Lachy Crothers responsible for brewing the beers, they enjoyed an overwhelming response from their local community at an open day during Brewsvegas, with reports of queues of up to 45 minutes to get beer.

They will be running a three vessel, 25 hectolitre brewhouse and say their lighter beers – mid-strength and lager – have proven most popular to date.

Where did you expect to be at this stage?

David: We are currently about four to five months behind schedule. Our aim was to open in September 2016. Sales are not as far progressed as we had hoped for by now, with the resulting stretch on cash flows due to extra salaries, rents, etc in the meantime.

Knowing what you know now, and given the chance to start over, what's the one thing you would do differently?

I would be much quicker off the mark with the Development Applications. Make very, very sure you have a town planner that you can be confident in. Ask around and find one that has successfully done a brewery application before, get feedback from the owners and then get him – price should not be the only issue. You lose three months because the planner is an idiot and you lose $10,000 of prospective sales as a result.

Also, I would engage my local councillor right at the start (see below).

What has surprised you the most?

The amount of time and money spent on extra consultants, approvals, licenses, etc. Also, the cost of all the ancillary fitting out of the brewery. The cost of the brewing hardware was only about 25 percent of the total spend to get everything up and running. Electricals, plumbing, flooring, safety, cool room...

What has been your greatest victory to date? And your biggest mistake?

We received very bad press from the local councillor. He sent letters to locals advising them how to oppose our Development Application. He didn’t bother to discuss our operations before doing so.

We launched an email and Facebook campaign via our supporters that was so strongly opposed to his actions that he eventually sent a second letter out to residents advising them how we were a good business and welcome to the community. Our DA eventually went through with only one irrelevant objection.

Biggest mistake so far was putting the brewhouse too far back in the warehouse and so we had to pay a lot more to connect services to it. Better to have the brewhouse at the front of the warehouse or located close to the plumbing and electricals to minimise the cost of connections.

What advice do you have for anyone following in your footsteps?

Resign from your job and do it full-time. Part-time will kill you.

Describe the process of starting a brewery in five words?

Really, really, really hard work.

If you would like to attend the Brewery Startup Panel on May 19 during Good Beer Week, which includes entry to the AIBA Exhibitor Tasting, please register your interest here.