Brewery owners launch their businesses to brew beer, but often that's something they rarely get to do.

Day-to-day, running a brewery can mean handling invoices, stock ordering, and managing production schedules; in an industry where margins are tight, time can be a brewery owner, head brewer or sales manager's most finite resource – not least when one person covers all three roles.

Hoping to help make such challenges more, well, manageable is Abbl, a new brewery management software built to streamline brewery processes.

It's been created by a family-run business who should know a thing or two about what they're doing too: the founders come from a family-run brewery, Wollongong’s Five Barrel Brewing. Since the brewery poured its first beers in 2016, Five Barrel has been a family affair, with Phil O’Shea running the indie brewery alongside his sister, Lucy Timpano, their parents, and their other sibling Tim.

Lucy says they’ve all had to wear many hats within the brewery and, in the early days, running it while their families were growing at the same time was a constant battle.

“[Phil and I] started having our families and life just got really complicated really quickly,” she says. “I took some maternity leaves and then my job became Phil’s job and he started to get a bit snowed under.

“At that point, it was just a family working in the brewery; we didn't have any extra staff to rely on; it was just us doing absolutely everything from ordering ingredients to doing the deliveries.”

It's a story you hear often and, before long, Phil and Lucy decided to draw upon their own professional backgrounds (in IT and accounting respectively) to build a program that would eventually become Abbl. Lucy says the goal was to free up their own time by automating a lot of essential tasks, from ordering ingredients to delivering beer to pubs and bottleshops.

“We were looking at ways to alleviate some of those issues,” she says. “Especially around ordering, inventory management and production and things like that; everything that you just can't drop the ball on.”

Although there are other management systems out there for production, when they started working on Abbl four years ago, nothing quite suited their needs. She says the price of existing management tools for small breweries could often be prohibitive and there were processes and a level of flexibility they wanted but couldn't find anywhere else.

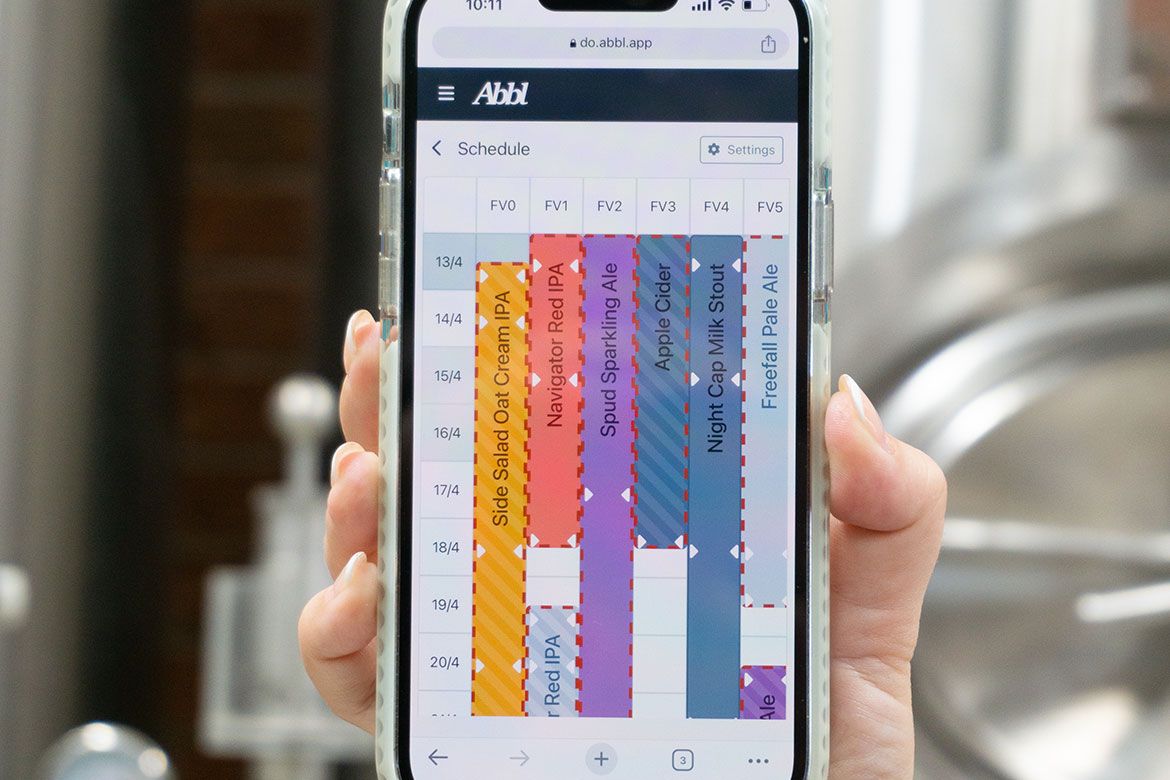

“Pretty much everything you need to do in your brewery, you can do an action within Abbl that replicates that," she says. "Everything from contacts to inventory management to sales to logistics.

“We've built a lot of automation in so you don't have to keep track of absolutely everything, and Abbl will tell you everything that you need to do. So, if you schedule a brew for eight weeks ahead, then two weeks before it will tell you, ‘Hey, you need to put an order in today to have those ingredients.'”

Beyond production, Abbl also helps track beer sales and is used by their sales team on the road.

“Once you've put an invoice in, you can allocate that to a delivery run and to a user who will get a map and list of all the deliveries they need to do,” Lucy says.

“As an accountant, I used to spend so much time on excise reports, container deposit scheme reports, and inventory management. Abbl does everything for me now: I just push a button and the numbers appear.”

In the years Five Barrel have been using Abbl, they’ve grown significantly and Lucy says they wouldn’t have been able to do it sustainably, and would have risked being swamped by the business rather than focusing on it.

“When we started Abbl, we were doing about 20,000 litres a year and now we're doing over 200,000,” she says.

“We’ve hired more staff, they've been using it really easily, and it's definitely given us more opportunities to work in other parts of the business.”

Early last year, Lucy and Phil started developing Abbl into a tool for the rest of the industry after being accepted into the University of Wollongong’s iAccelerate incubator. The business development program has also supported other local beer businesses, such as the liquid yeast makers at Mogwai Labs and keg software business Binary Beer.

“[After that], we really started focusing on getting a product out there to show other breweries what we've done,” Lucy says.

They've also been working with Curly Lewis' head brewer and brewing industry consultant Scotty Morgan to test their software out elsewhere.

“He's been instrumental in helping us work out the bugs," Lucy says. "We've been using Abbl for so long, you get really focused on our way of doing things, so having Scotty come in and push back and question it has been really great.”

The other early feedback they've received from breweries has been positive, with the fact they're an Australian-based business really exciting customers.

“It's really flexible," Lucy says. "We can go from a contract brewer, who's really just interested in inventory management, to a brewpub, who is interested in inventory management and production, all the way up to a production brewery of our scale and larger, really.

“We want to be with somebody from 20,000 litres up to 200,000-plus. This kind of software can be a little bit harder for the little guys and it’s such a big problem because it's the little guys that need the help to grow. But if you don't reduce the amount of time that you're sitting at the computer, you're not going to be able to grow.”

After two challenging and ever-changing years caused by COVID, 2023 is shaping up to be an even tougher year for brewers, with the price of raw materials, energy and just about everything going up and multiple breweries going into administration or up for sale. Lucy says their hope is that Abbl can help breweries survive this difficult trading period by providing a straightforward way to really keep an eye on their margins, sales and the cost of every batch of beer.

“The problem is, not every brewer is a businessperson," Lucy says. “If you can't tell if you're making a profit on the batch of beer that you brew today, you're really going to struggle in a couple of months, and I think a lot of places are finding that.

“Keeping track of your costs is the hardest part of a business but it's the easiest way to get yourself into trouble.”

Although Lucy predicts this tough market will continue until at least summer – and points out that margins in the beer industry are tight in the first place – she says Abbl has already helped one brewery grow sustainably: Five Barrel.

“In our brewery, we grew organically without the need to take on debt or anything like that, because we managed our cash flow.”

As a launch promotion, Abbl are offering breweries listed in The Crafty Pint's directory 30 percent off their first six months on the platform if they subscribe before May 31, 2023. For access to the discount, email Will.