There's a good chance you've been been hearing a lot about this thing called climate change and how we all have to do something about it. Well, instead of grabbing a beer and waiting for things to blow over, Batch Brewing Co owner Christopher Sidwa and the brewery's bar and supplier relations manager S. Cree have come up with a number of environmental initiatives as they to work towards running a more sustainable, greener brewery.

Plenty of power is required when it comes to brewing beer at an industrial scale, so being creative in finding ways to reduce the impacts that come from the daily running of the brewery is a step in right direction for breweries wanting to bring down their carbon footprint. Breweries are also one of the largest industrial users of water and are faced with many environmental issues from the farm to tap, with water and energy being two of biggest considerations. The Oxford Companion To Beer defines these impacts by three streams: upstream and raw materials used to make the beer; operations and resource; and downstream transportation and distribution.

Chris says: “I mean, I’m a bit of a hippy, I’m a bit of a green person myself. This is a very power hungry business; there’s no way of getting around the fact that you have to use diesel and natural gas to generate beer. We want to be as green as we possibly can – I mean ideally we’d be completely carbon neutral, but all of this takes time and resources so the bigger our business gets the more able we are to do these kinds of things.

While it is nice to make money, it also enables us to do this – so it’s kind of like we are a profit-driven organisation but hopefully it’s for a good reason.”

In the quest to make the brewery more energy efficient, Chris started looking into cleaner energy companies to use, choosing clean energy company Tasmanian Hydro, the largest generator of clean, renewable energy in Australia, to power the brewery.

“Tasmanian Hydro is a generation company, they own hydro facilities in Tassie," Chris says, "but they have a retail arm and anyone in the country can buy power from them. It doesn’t mean that it’s getting generated at the Tasmanian facility, but at least that amount of green energy is going to the grid.

"So we’re buying from a maybe a coal fire plant but there’s still an equal amount getting generated in a green way.”

Says Cree: “There’s no way of getting around the fact that this place never turns off. Like when we leave at night half of this place is still just full-tilt the whole time. We can’t just be like, ‘For the next 12 hours the fermenters are off.’– it’s 24/7, 365. That’s our only option.

"The first step is approaching how we’re going to take this on and work towards easing up more things out there [in the taproom].”

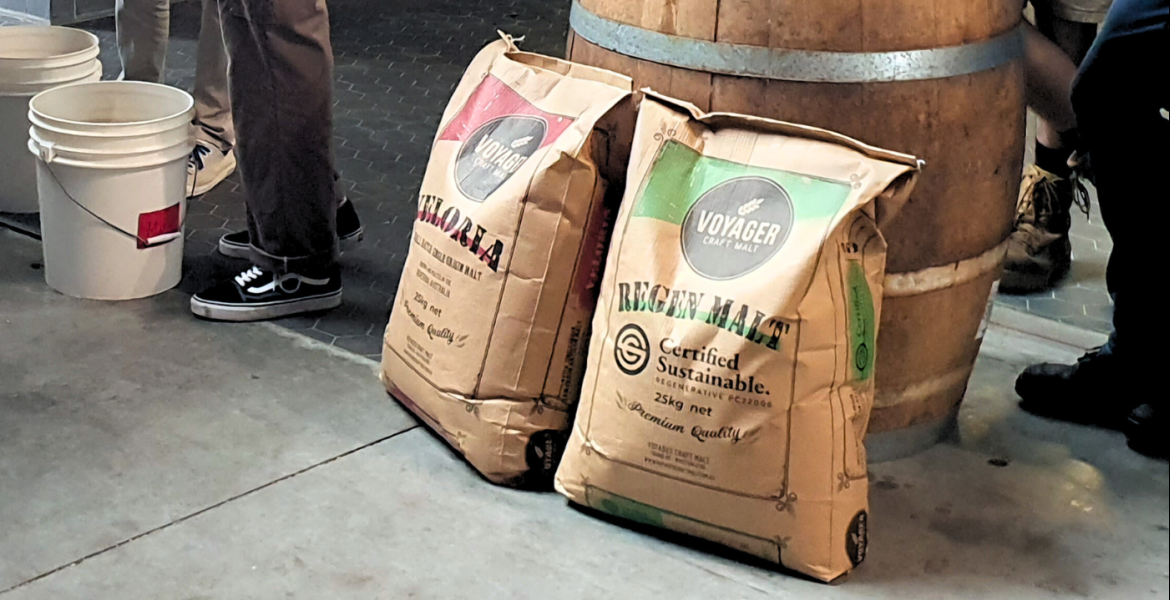

Batch has been involved in a number of projects that support regenerative farming practices and sustainable farming, including its partnership with Voyager Craft Malt.

“A lot of that had to do with encouraging farming practices," Chris says, "so by knowing who is actually doing the farming, you have some input into what their doing, how many chemical resources they’re using to grow, what kind of practices they’re using but also making it a much more direct supply chain so what’s happening on the farm only has to travel a short distance to the malthouse, and then from the malthouse it’ll come then straight to us.

“Voyager is one of the greener malt businesses in the world. They use a lot of renewable energy, a lot of waste products in generating their power and a lot of their wastewater goes back onto the farm for irrigation. So partnering with them was a no-brainer; having them as close as they are, with a direct route to us, it just cuts down on diesel fuel.”

Cutting down on distribution travel time to save fuel was only one of the reasons why Batch started their carbon initiative, offsetting the carbon used in the day to day running of the brewery. Another reason was Chris’s adamance to keep the majority of the Batch beer supply in Sydney.

“That’s looking up our supply chain," he says, "but the diesel initiative came from me being a pain in the ass to [co-founder] Andrew about not selling beer outside of Sydney. Yes, there’s a local feeling and it’s good to be able to come to the brewery and experience it and have it at your local, but for me it always felt very stupid for us to send kegs to Melbourne when effectively the beer market is what it is, there’s going to be how many pints poured in a weekend?

"If I send a keg down there that means a brewery working down there loses a tap and has to send their beer somewhere if they want to sell it. So they might be sending their beer to Sydney, and now we have two kegs traveling in opposite directions burning diesel fuel for no reason other than because I wanted to be ambitious and take over Melbourne. So it just seems stupid, a waste of fuel and a lot of energy.”

Cree adds: “Because everything has to be cold-shipped as well. It can’t just be chucked onto the back of any company shipping that is going to Melbourne. It has to be put on a cold truck and sent cold with everything else.”

She started investigating options on the internet and found Greenfleet, an environmental, not-for-profit organisation that helps individuals and businesses offset emissions from cars, planes and the household, planting more than nine million trees and offsetting over 2.8 million tonnes of carbon.

Cree says the aim wasn't "to bite off more than we could chew, in some ways it was to make sure that this part of our business is taken care of.”

Chris adds: “The last time you booked an airplane ticket, did it have an option somewhere to offset the carbon? And did you do it? I’m guilty of saying no, fuck this, and click no to all of the options; like, I’m paying a fortune I don’t need to spend another $40 on this flight, but when you put it in perspective I think what Greenfleet has exposed to us is that it doesn’t cost a lot.

“They use their best estimates to figure out what was being burned to ship a pallet to say, Melbourne or to Perth, and they just added a little bit and said are you comfortable with that amount? And right now we’ve settled on $15 per pallet.

“In addition to what we send interstate we found out it's very cost effective to also offset all the diesel that we burn. Every time the guys fill up at the petrol station, we put into our system the number of litres that we’ve used [and] Greenfleet knows exactly what we’ve used and what a litre of diesel creates and we pay for all that as well so whether it’s interstate or local it's carbon offsetted from the point of leaving the brewery to the point of the customer.”

Chris has long been an environmental advocate, incorporating green ways of working on the brew floor and at the farm, and highlighted the importance of the B Corp certification, which is awarded to big businesses that work towards social and environmental excellence – both 4 Pines and Stone & Wood hold the accreditation.

Chris says: “I genuinely believe that what they're trying to do by holding businesses to a higher standard is where industry needs to go. I can't fault generations before for anything they've done but they've also left us with a global economy that's reaching a tipping point.

"If you watch any of the Al Gore movies, or anything like that, Food Inc, we've got a horrible food system that pollutes. We're buying agricultural raw materials and using a lot of diesel fuel, using a lot of chemical fertilisers; so where we can have impact is where we can choose our suppliers and how we choose to then distribute.”

Batch started offsetting its carbon use last November and, says Cree: “It has amassed quite quickly ... by the time it hits twelve months it looks like we will have planted almost two hundred trees – well, facilitated two hundred trees being planted.”

Chris adds: “The more we talk about it, the more we do, maybe we’ll get supported more and the more people support what we’re doing, the more we can do to make positive change.”

You can read other entries in the Going Green series here. If you've got an initiative underway that we might like to know about, get in touch.

About the author: Hannah Louise Grugel is a craft beer-loving, Little Hop-blogging writer living in Sydney.