Gather 'Round, People

The beer industry is one of the most collaborative you'll come across, and in recent years it has placed a greater focus on sustainability than ever before. And if you're looking for a story that highlights both traits to the full, this is it.

At its heart is the fact that South West WA-based brewery Rocky Ridge’s base malt is now Certified Sustainable, which results in an impressive reduction in emissions compared with those from conventionally farmed malt. All well and good, but it gets even more impressive once you start to explore the tale of how this came to be.

It's a tale that stars operations of all different sizes from various strands of the brewery supply chain coming together to grow and brew something different. Along the way, Tolga Farm, Bintani, Certified Sustainable, Joe White Maltings, CBH Group and Rocky Ridge all played pivotal parts.

For the most part, it's also a story of locals joining forces to create something new and better, yet the catalyst for change actually took place thousands of kilometres away: at one of America’s best-loved craft breweries, Russian River.

To most avid beer lovers, the Santa Rosa-based icon is best known for beers such as Pliny (both Elder and Younger) and barrel-aged sours like Consecration, but the brewery has long focused on sustainability too. And it was there, ahead of the 2022 Craft Brewers Conference (CBC), that Phil Meddings, who runs Bintani alongside brother Dale, first got talking to Rocky Ridge co-owner Hamish Coates about the farm brewery's own approach to sustainability.

“I went up and started chatting to him,” Phil recalls. “We had a few beers together and, towards the end of it, he told me about Tolga Farm, their sustainable barley, and how they wanted to get it malted.”

Before meeting Hamish, the Bintani team had been eager to help brewers and distillers create drinks with fewer emissions. So, a short time later in Minneapolis during CBC, Phil introduced Hamish to Daniel Baillon, Joe White Maltings’ key account manager.

“It was just a really good time because everybody was in the same place at the same time and passionate about getting it done,” Phil says.

Once they were all back in Australia, the Bintani and Joe White teams visited Rocky Ridge's brewery in Jindong to work out a plan. They invited Ash Truscott from Certified Sustainable, a not-for-profit agricultural organisation that provides independent certification for positive environmental, social and governance processes, to join them. It means the malt's journey from grain to glass is completely accounted for, with the NFP accrediting Tolga Farm, Bintani and Rocky Ridge.

From Little Things...

It was a plan centred around the work of Brendon and Gab Savage at Tolga Farm, who have been improving the quality of their soil for years, after joining forces with Australian Soil Planners – Australia’s largest group of sustainable farmers – more than a decade and a half ago.

“We were trying to fix our soil up, so we grow crops without pouring so much synthetic fertiliser on them,” Brendon told The Crafty Pint. “It's been a very long journey.”

Brendon felt traditional farming practices weren’t protecting the land his family had been farming in Western Australia’s Wheatbelt region for many years, so they started learning how they could adapt their methods.

“I came home from uni and enjoyed the conventional farming style because you just put [nitrogen] on it and you grew a good crop," he says. "And you put more on and you grew a better crop.

“But then I started to see that if you kept doing it forever, it wouldn’t be sustainable in the long-term.”

Nitrogen-based fertilisers are used heavily in farming across the planet and, while they help crops grow, they are a major source of nitrous oxide, a pollutant that stays active in the atmosphere for around a century and is 300 times more potent when it comes to warming the planet compared with carbon dioxide.

Head to Tolga Farm today, and you'd find the couple describing themselves as hybrid farmers: using both traditional and sustainable farming practices for crops and livestock. While they’ve been focused on soil health for a long time, it’s only since lower emission farming became a talking point that people started paying attention.

“It didn’t really get a lot of traction until the community and everyone started talking about low emissions,” he says. “I was knocking on doors and seeing if anyone would work with us and got laughed at a little bit.

“My key thing was the soil, and growing the crop without damaging the soil every time you plant a crop. Our soil organic carbon is nearly double the average of the Wheatbelt in WA, and our growing inputs of synthetics are very low, and yet we still grow a pretty handy crop.”

Eager to get his barley malted, Brendon was introduced to Hamish a couple of years back by a mutual friend and, since then, they’ve been working out how to get Tolga Farm’s malt into Rocky Ridge’s beer. It ticked multiple boxes for the latter: grown in Western Australia, single origin, and responsible for far fewer emissions than regular malt.

“Hamish just grabbed the bull by the horns – he’s really keen to do the right thing,” Brendon says.

Since then, the level of collaboration has impressed everyone involved, including Brendon, who says it was important to get the grain handlers at CBH Group on board to work with Joe White. And, in turn, how important it was for Joe White to be able to handle single-origin grains at their vast Perth facility that was built to malt 300-tonne batches.

“That's the big thing I love about it,” Phil says. “Everyone contributed.”

...Big Things Grow

At Rocky Ridge, Hamish and Mel Holland have been committed to brewing sustainably since they launched – you can read about their Greener Pasture initiatives here. Now, after taking possession of 320 tonnes of malt from this multifaceted project last month, they have a Certified Sustainable base malt for their beers.

“We still pinch ourselves a little bit,” Hamish says. “It really speaks volumes about how collaborative the entire industry is, and how everyone wants to see better sustainability across the board."

If you want an idea of the disparity in size between some of the partners involved in this project, the Joe White plant in Perth isn’t just Australia’s largest, it’s the second biggest in the world operated by the world's largest malting company, Belgian-based multinational Boortmalt.

“Joe White had to find a space in their schedule to be able to get it through their malting plant,” Hamish says of Tolga Farm's single-origin crop.

“Then we had to coordinate in such a way that it wasn't getting put into their great big blending tanks or silos – it was coming straight out and coming to us.

“I was blown away by how much energy had to go into getting it off the ground in the first place.”

By virtue of the malt being fully traceable, Rocky Ridge are able to calculate the exact carbon footprint of the entire supply chain, from paddock to pint. As a result, they can offset any emissions they're unable to remove entirely through Carbon Neutral Australia. Beyond the satisfaction they take from reducing the impact of the malt on the climate, the fact their base malt comes from a local farm with which they have a close connection gives them an even better story to engage drinkers.

“All we're hoping is that this opens everyone's eyes to the fact that perhaps we should be having more of a conversation about using highly localised ingredients,” he says.

“We should be having more of a conversation about what goes into making that ingredient in the first place. It's not just about our own direct input into the final beer, it's about how we can work with our supply chain, how can we find individual farmers to work with, and can we support that as an industry?”

Given craft beer adds value to Australia’s crops, Hamish believes the industry is uniquely placed to lead conversations about cutting emissions from farming while championing local agriculture at the same time.

“Ultimately, the quality of the products is not just down to how we treat it as brewers, it’s mostly down to raw ingredient quality,” he adds.

“I still firmly believe in making sure that every single step along that chain is done in the best way possible, not just to the best quality possible, because they're not mutually exclusive: it needs to happen together.”

It’s a vision that’s been well supported by Bintani, as evidenced by Hamish's recollections of his first beers with Phil and Dale at Russian River.

“Their eyes lit up about the idea of Certified Sustainable and having a higher regard for the provenance of the barley that we have," he says. "Looking at single-origin and looking at the better ways that barley can be grown.”

Looking ahead, he is optimistic that Certified Sustainable base malt can become an industry standard.

“Ultimately, the end goal is for this to become more normal,” he says. “With Bintani’s support and with Joe White’s support, we are hoping that we can actually have a Certified Sustainable and carbon-neutral malt source for Western Australia at the very least.”

The Story Of Something Much More

Bintani is the first Certified Sustainable brewing and distilling ingredients provider in Australia, and these positive outcomes in Western Australia have led to the development of something new in the country's east too.

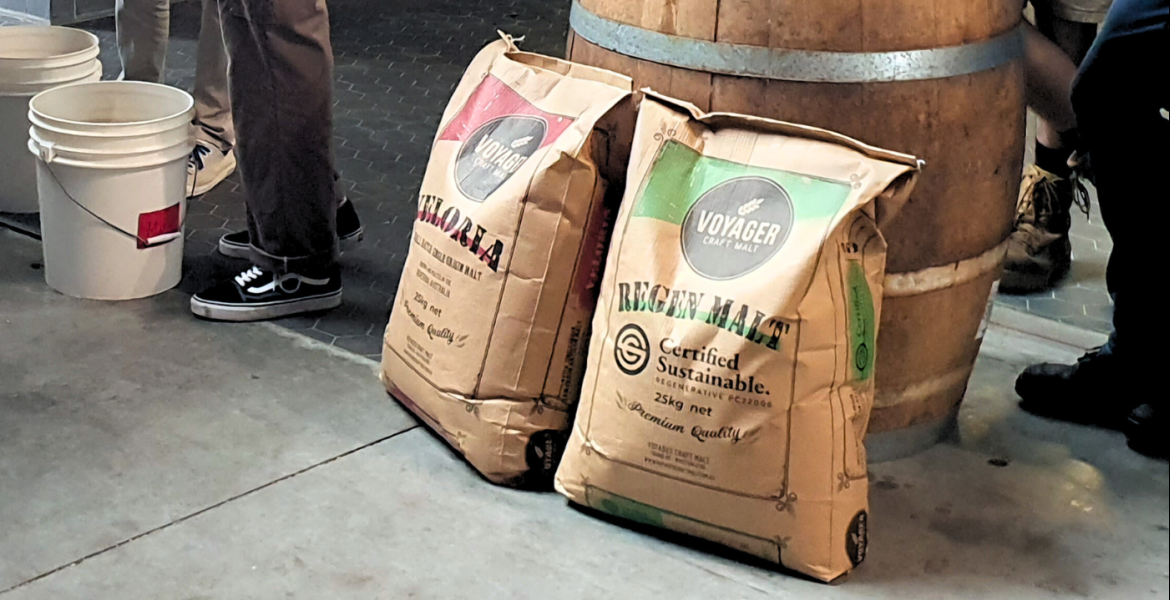

Last week, they officially launched the 2023 Joe White Signature Malt, a project we first wrote about here. The line debuted in 2018; this year, it has been sourced from the Pearse Family Farms in the northwest Victorian town of Donald and beyond being single-origin it too is Certified Sustainable. Certified Sustainable's data shows that barley grown within their regenerative farming network results in an impressive 60 to 80 percent reduction in greenhouse gas emissions compared with barley grown conventionally.

After their meeting at Rocky Ridge last year, Phil and Dale began visiting farms on the East Coast to see if they could source more Certified Sustainable malt and, as Phil puts it, "drawing this closer connection between the growers and the beer drinker.

“That’s just constantly developing.”

As interest in working with more environmentally-friendly malts grows, the intention is to develop a greater range of low-emission options, including specialty varieties – provided the brewer demand is there.

Barley has always been a significant contributor to emissions for brewers and distillers alike; now they have a more sustainable option, Phil sees the potential for change.

“If we can provide a market for and shift demand towards this,” he says, “then it’s going to have a big impact.”

Photo at the top of this article provided courtesy of Tolga Farm.